Kaarvi Braze India Private Limited

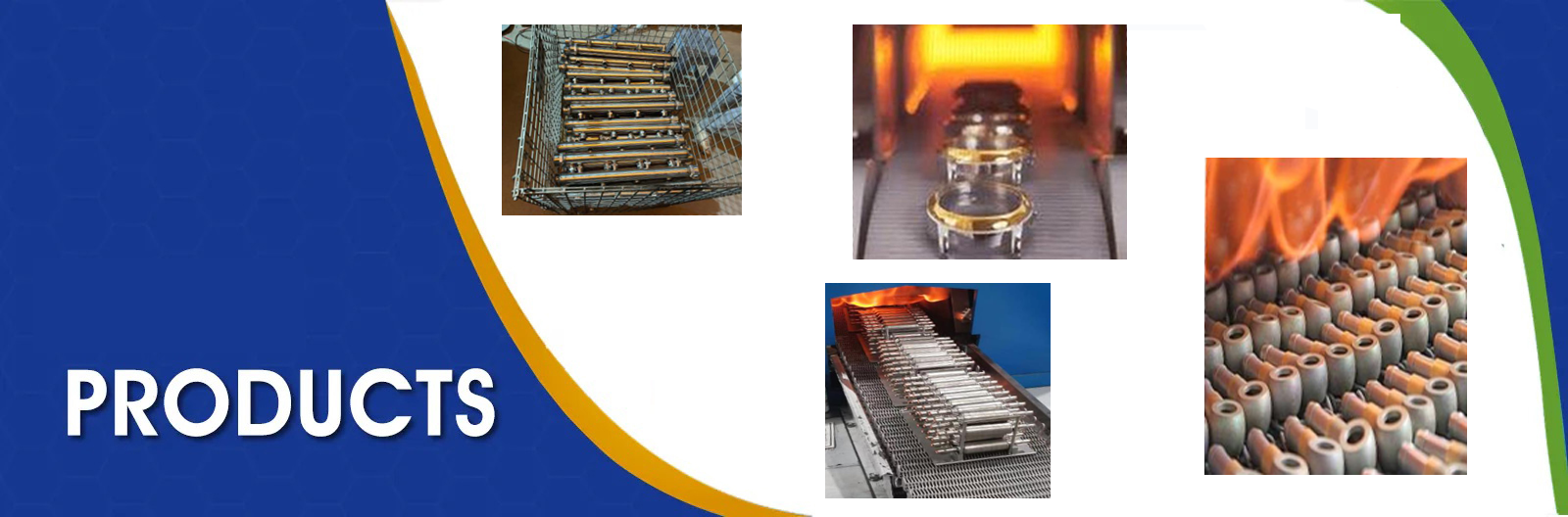

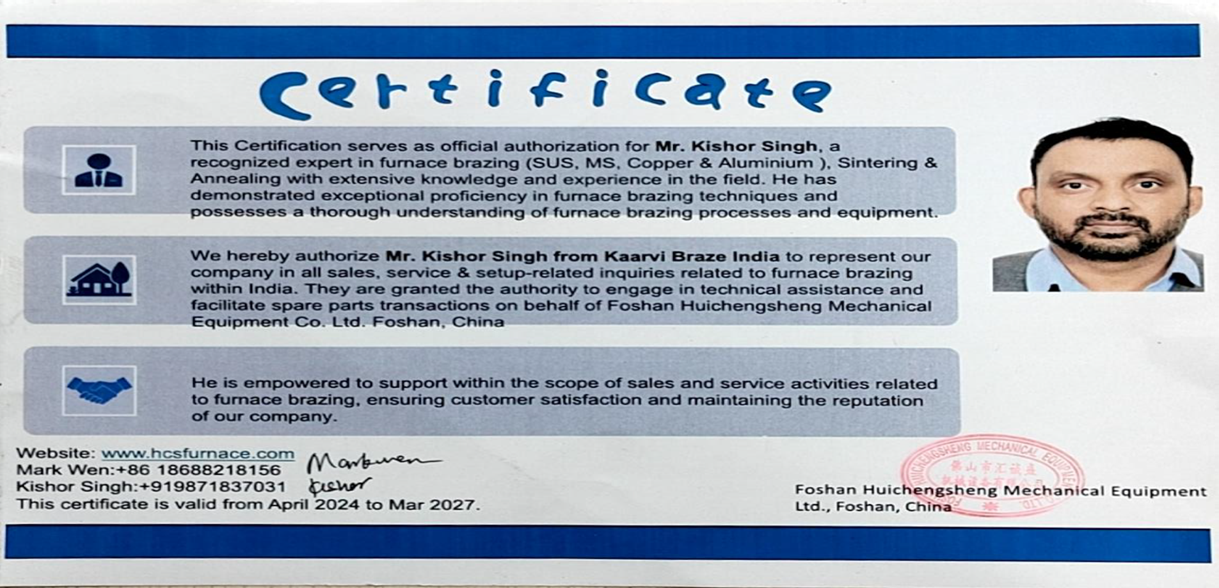

We Kaarvi Braze India Pvt. Ltd., serve job work in Furnace Brazing operations, for a diverse range of materials including Mild steel (M.S.), Stainless steel (SUS), Copper, and Aluminum. Our expertise extends to heat treatment processes such as Sintering & Annealing, also for various components. We also offer comprehensive services, starting from setting up new furnaces by providing technical training, consulting expertise, and conducting regular health checkups for equipment. We manage critical spare parts, including conveyors and heaters, ensuring uninterrupted operations.

Moreover, we specialize in cost-saving initiatives, such as replacing traditional copper paste with innovative solutions like copper chips, wires, or profiles.

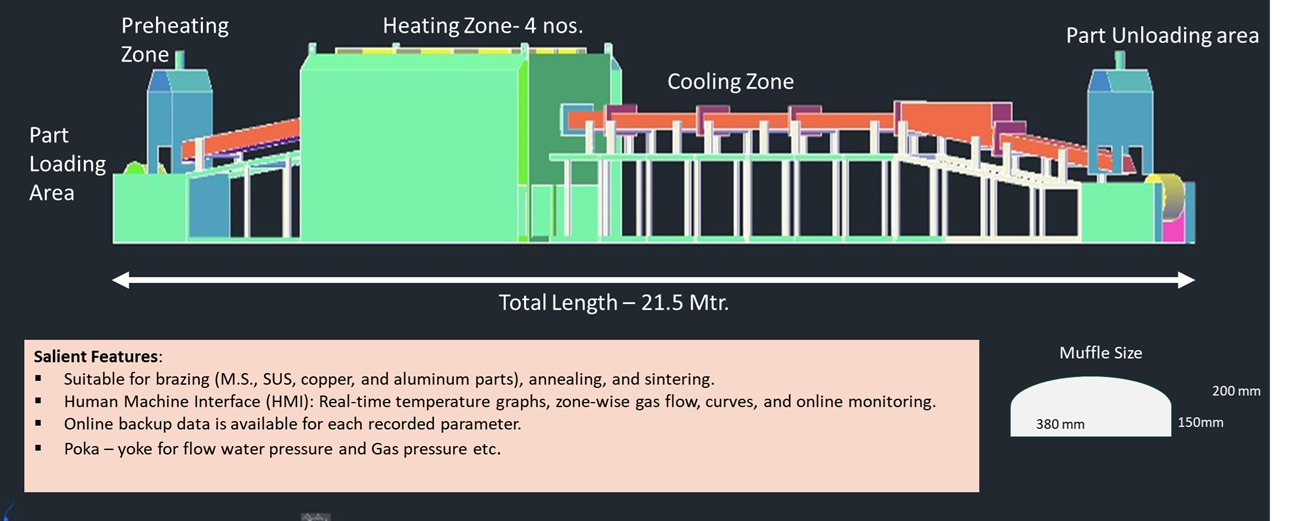

Plant Overview - Furnace Brazing/Annealing

Establishment of a factory in an area of approximately 1,500 Sq. Mtr.

Establishment of a new furnace brazing/annealing facility.

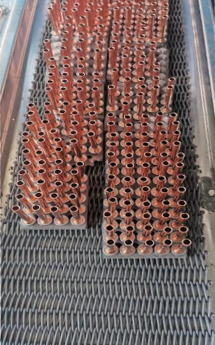

Kaarvi Braze boasts a team of capable individuals with 18 years of experience, possessing expertise in furnace brazing components pictured below:

Applications

- Steel to Steel Copper Brazing

- Steel to Steel Nickel Brazing

- SS Brazing with Copper

- Steel to Steel Copper Silver Brazing

- Steel to Steel copper phosphorus bronze – Brazing

- MS Sintering

- Copper Sintering

- Bronze Sintering

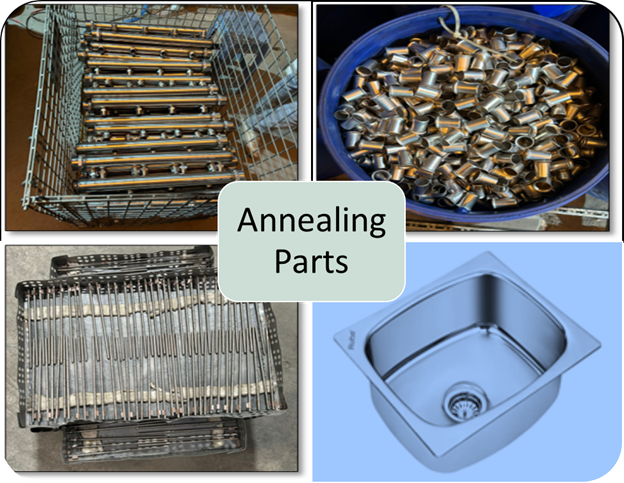

- Annealing Process – MS & SS Grades

Furnace Process Parts in Kaarvi Furnace – 1/3

Furnace Process Parts in Kaarvi Furnace – 1/3

Furnace Process Parts in Kaarvi Furnace – 1/3

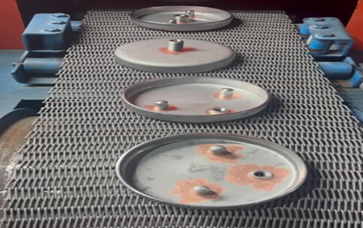

Process Parts in Kaarvi Furnace – 2/3

Brazing Part Supplied to Micro tools India [OEM – HONDA]

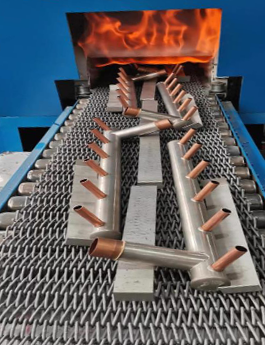

Potential Process Parts in Kaarvi Furnace – 3/3

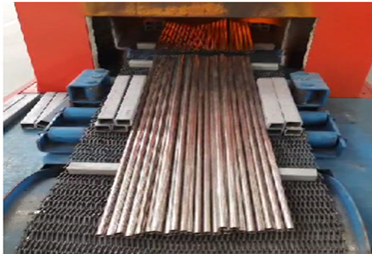

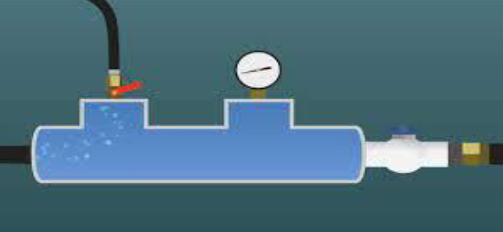

Potential Process for Tubular & sheet metal–1/2

Potential Process for Tubular & sheet metal–2/2

Customers

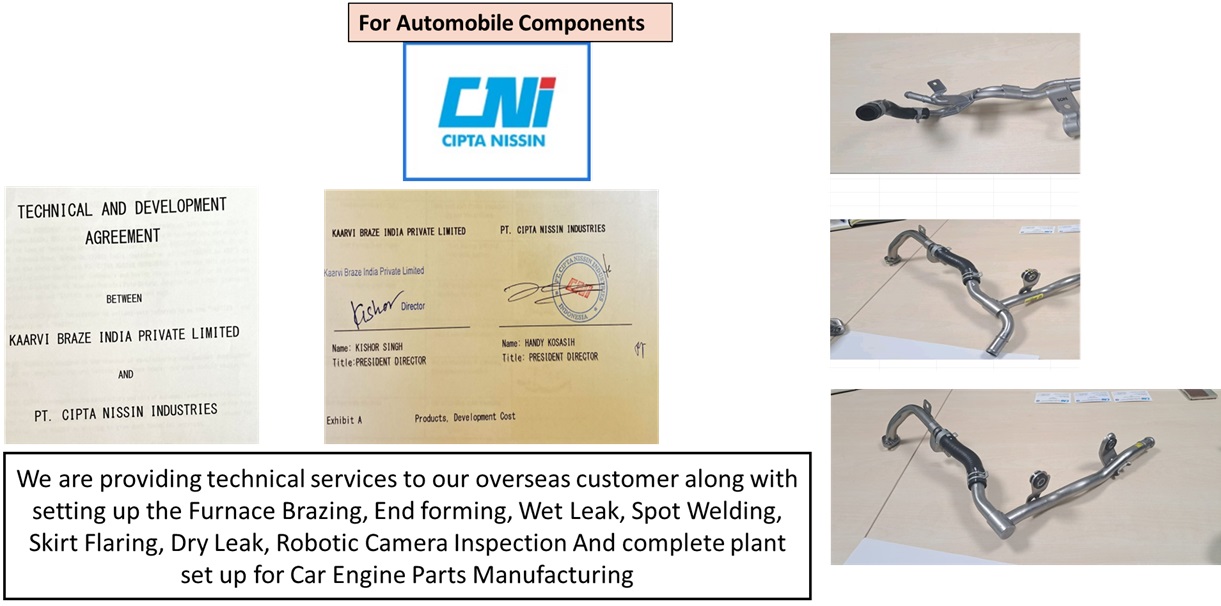

Overseas Customers

Overseas Customers For Brazing Plant Set up

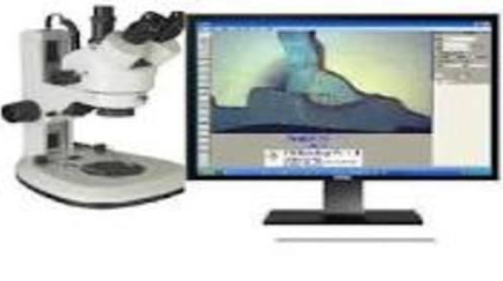

Certification

Kaarvi Furnace 3D Sketch

Sales and Services

We also offer comprehensive services, starting from setting up new furnaces to providing technical training, consulting expertise, and conducting regular health checkups for equipment. Additionally, we manage critical spare parts, including conveyors and heaters, ensuring uninterrupted operations.

Moreover, we specialize in cost-saving initiatives, such as replacing traditional copper paste with innovative solutions like copper chips, wires, or profiles. These initiatives not only optimize processes but also aim to enhance efficiency and minimize rejection ratios, further showcasing our commitment to delivering high-quality and sustainable solutions.